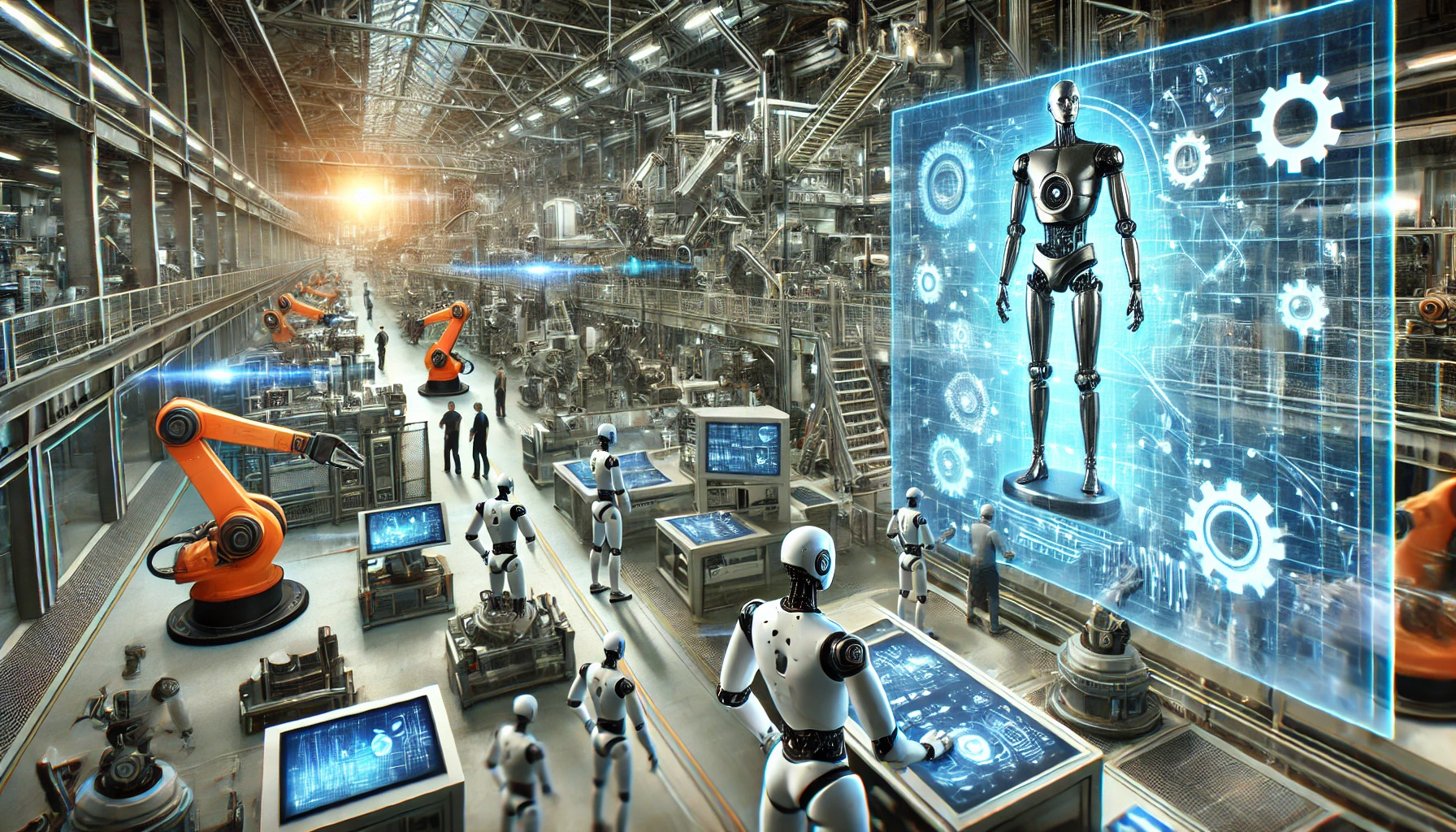

The manufacturing industry is in a real revolution thanks to the integration of AI (artificial intelligence) and automation. These technologies improve efficiency and productivity and change the way a company designs, produces and distributes its products. We explore how AI is fundamentally changing the manufacturing industry and what benefits and challenges it brings.

Increased efficiency and productivity

One of the advantages of integrating AI into the manufacturing industry is certainly the increase in efficiency and productivity. In fact, smart automation systems are able to work 24/7, reducing downtime and consequently increasing production. Furthermore, AI analyzes enormous quantities of data in real time and thus optimizes production processes, identifying areas for improvement and critical issues.

For example, some manufacturing plants use AI robots to assemble products with greater precision and speed than human workers. These robots also quickly adapt to new instructions and learn from data to continuously improve their performance.

Predictive maintenance

Another significant benefit of AI in the manufacturing industry is predictive maintenance. Thanks to sensors and Machine Learning algorithms, these maintenance systems monitor the status of machines in real time and make predictions about when they might fail. Naturally, in this way the company can limit maintenance interventions only to when they are really necessary, reducing costs and preventing costly downtime. For example, a predictive maintenance system can analyze the data coming from a machine’s sensors to detect signs of wear and anomalies before a fault occurs, thus planning a targeted maintenance intervention and avoiding interruptions in production.

Quality improvement

AI in the manufacturing industry is also useful for improving the quality of products. In fact, through advanced artificial vision and machine learning techniques, the quality control system can identify defects and imperfections with great precision, thus reducing waste and ensuring the highest quality on the market. For example, some production lines use high-resolution cameras combined with computer vision algorithms to inspect products in real time. Thanks to these mechanisms, minor defects that may escape the naked eye can be detected, so that only products that comply with standards are released.

Challenges and Considerations

Despite its many benefits, integrating AI and automation into the manufacturing industry is not without its challenges. The main one concerns the impact on employment: in fact, although automation can increase productivity, it could also reduce the need for human labor for certain tasks, thus establishing a decrease in available jobs.

Another major challenge is data security: the implementation of AI requires large quantities of sensitive data, and this raises concerns about privacy and cybersecurity.

Therefore, while on the one hand AI and automation can undoubtedly transform and improve the manufacturing industry, offering numerous advantages in terms of efficiency, productivity and quality, on the other hand it is essential that companies invest in adequate security measures and face the challenges associated with this technology in terms of employment to ensure a smooth and sustainable transition.